This kind of product is assembled by three eccentric multi-layer metal hard-seal butterfly valve body parts and a small single-acting, double-acting pneumatic piston mechanism.

Professional Service:

Hotline: 086-0577-67353999

Fax: 086-0577-67369596

E-mail: 2850665190@qq.com

Overview

This kind of product is assembled by three eccentric multi-layer metal hard-seal butterfly valve body parts and a small single-acting, double-acting pneumatic piston mechanism. The valve body parts adopt three eccentric sealing structure, which makes the valve tighter and tighter when opening and closing. Therefore, the sealing performance is effectively ensured. When opening, the valve plate is instantaneously separated from the sealing surface of the valve seat, and the friction torque is effectively reduced, so that the valve is opened and convenient and labor-saving. The actuator adopts high-quality aluminum alloy profiles, and the structure is novel, simple, stable, and reliable. It can be adjusted or cut off with electric valve positioner or solenoid valve. At the same time, this kind of product can also be used with electronic actuators. This kind of products are widely used in metallurgy, electric power, petrochemical and other industrial sectors to control various types. Gas, liquid medium.

The main technical parameters

Valve body

Type: straight through casting butterfly valve

Nominal diameter: DN80 ~ 900;

Nominal pressure: PN0.25, 0.6, 1.0, 1.6MPa

Connection type: wafer type flange connection convex surface

Main body and valve plate material: WCB (SCPH2) CF8 (304), CF8M (316)

Stem material: 2Cr13, 304, 316

Applicable temperature: normal temperature type -40 ~ 250 °C, medium temperature type -40 ~ 450 °C, high temperature type -40 ~ 700 °C

Filler: flexible graphite, asbestos braided packing

Remark: The valve plate sealing surface is surfacing with cobalt-based alloy multi-layer sealing surface, which is 316L and expansion surface ink sheet interlayer

In-valve assembly

Valve plate type: three eccentric butterfly plate

Sealing type: multi-layer composite seal, elastic seal

Leakage: DN80~500 relative to zero leakage, DN600 or above JB/T8527-9710×DNmm3/s

Adjustable ratio: 30:1

Executive agency

Type: AT-DA double acting piston actuator, AT-SR spring return actuator

Air source pressure: 0.4 ~ 0.6MPa

Air source interface: M10×1, M12×1.25

Output angle: 70° or 90°

Ambient temperature: -20 ~ +80 ° C

Accessories: solenoid valve, travel switch

Rated KV value

| DN | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Coefficient | 220 | 340 | 530 | 770 | 1360 | 2130 | 3060 | 4160 | 5450 | 6900 | 8500 | 12200 | 16600 | 21700 | 27100 |

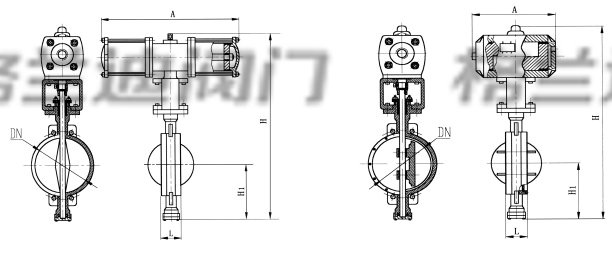

Dimensions

| DN | L | A | H1 | H | Increased "H" size with handwheel mechanism | ||||

|---|---|---|---|---|---|---|---|---|---|

| clips | flange | QGH | AT | QGH | AT | ||||

| 80 | 49 | 114 | 290 | 82 | 260 | 240 | 120 | ||

| 100 | 64 | 127 | 560 | 295 | 95 | 300 | 285 | ||

| 125 | 70 | 140 | 560 | 295 | 120 | 375 | 360 | ||

| 150 | 70 | 140 | 560 | 308 | 150 | 480 | 450 | ||

| 200 | 71 | 152 | 630 | 308 | 215 | 590 | 560 | ||

| 250 | 76 | 165 | 630 | 474 | 265 | 660 | 610 | 125 | |

| 300 | 83 | 178 | 630 | 474 | 295 | 810 | 750 | ||

| 350 | 92 | 190 | 870 | 592 | 325 | 970 | 910 | ||

| 400 | 102 | 216 | 870 | 664 | 365 | 1050 | 990 | 140 | |

| 450 | 114 | 222 | 1100 | 664 | 400 | 1150 | 1050 | ||

| 500 | 127 | 229 | 1100 | 732 | 440 | 1210 | 1160 | ||

| 600 | 154 | 267 | 1100 | 732 | 505 | 1510 | 1390 | 160 | |

| 700 | 165 | 292 | 1400 | 935 | 540 | 1570 | 1490 | ||

| 800 | 190 | 318 | 1400 | 935 | 600 | 1700 | 1650 | ||

| 900 | 203 | 330 | 1400 | 935 | 650 | 1850 | 1760 | ||