Goodlad to provide our clients with high-quality Gas pressure regulator products. We would like to advanced design and manufacturing, customer-oriented service awareness, for the majority of users with high-quality products, satisfied with the service!

Professional Service:

Hotline: 086-0577-67353999

Fax: 086-0577-67369596

E-mail: 2850665190@qq.com

Overview

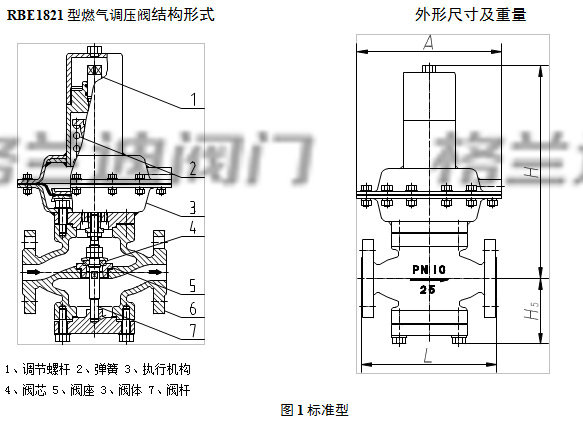

RBE1821 gas pressure regulating valve is an energy-saving pressure regulating valve that does not need external energy, but only relies on the pressure change of the medium to be adjusted to achieve automatic adjustment and stable pressure difference. It can be applied to gas pressure regulating systems, mainly for gas or gas pressure regulation.

The main technical parameters

Valve body

Type: three-way casting ball valve

Valve size: DN20~200

Rated pressure: PN16 PN25

Connection form: flange

Flange standard: steel flange according to EN1092-1

Sealing surface type: protruding surface

Material: CS (SCPH2)

X5Cr-Ni18 (SCS13A)

X2CrNiMo1812 (SCS14A)

Structural form: · Standard type (-5 ° C ~ +70 ° C) See Figure 1

Pad: type, tooth type and flat type

Material, F4/modified F4, stainless steel + graphite,

In-valve assembly

Valve core: single seat plunger type spool

Soft seal

Quick opening feature

Type: film type

CY100, CY280, CY400, CY600

Diaphragm material: nitrile rubber clip reinforced polyester fabric

Oil resistant rubber / fluoro rubber

Signal interface: internal thread M10×1

Ambient temperature: -30 ° C ~ +70 ° C

Seat leak rate (% of rated Kv value):

Soft seal

Less than 0.00001% or less

(ANSI B16.104-1976 level VI)

Dimensions: Refer to Table 2 on page 3.

Product weight: refer to Table 2 on page 3.

Performance

Rated Kv value: Refer to Table 1 on page 2.

Flow characteristics: quick opening

Machine action mode: pressure increase valve closed

Differential pressure adjustment range: Refer to Table 1 on page 2.

Pressure control accuracy: ≤ ± 8%

Additional specifications (manufactured according to requirements)

·Special inspection, material inspection (manufacturing record sheet)

Non-destructive inspection, steam inspection, low temperature inspection

·Flange back processing ·With drain plug

·Double packing ·Vapor jacket

·Forbidden oil and water treatment ·Forbidden copper treatment

·Special piping and fittings

·External bare bolts and nuts of SUS304 products

·Salt damage measures · Sand control, dustproof requirements

·Tropical specifications ·Cold area specifications

·Vacuum (use)

Table 1 Kv value Stroke Differential pressure adjustment range

| DN(mm) | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|---|---|---|---|---|---|---|---|---|---|

| Rated flow coefficient Kv |

6.3 | 8 | 20 | 32 | 63 | 80 | 125 | 220 | 320 | 420 |

| Rated stroke (mm) |

6 | 8 | 10 | 15 | 20 | 25 | ||||

| Maximum pressure in front of the valve |

≤25bar | |||||||||

| Pressure adjustment range(Bar) |

0.5~1.0,0.9~2.5,2.0~5.0,3.5~6.0 | |||||||||

Table 2 Unit:mm

| DN | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|---|---|---|---|---|---|---|---|---|---|

| A | 195 / 280 / 310 / 395 | |||||||||

| L | 150 | 160 | 200 | 250 | 290 | 310 | 350 | 400 | 480 | 600 |

| H5 | 100 | 100 | 120 | 125 | 145 | 155 | 170 | 215 | 220 | 260 |

| H | 285 | 337 | 344 | 344 | 386 | 396 | 406 | 410 | 460 | 480 |

| Weight(Kg) | 12 | 13 | 17 | 20 | 28 | 38 | 43 | 82 | 120 | 190 |